Recycled Plastics: Smarter, Greener Solutions

Recycled products made from rPET, rPP, rLDPE, rLLDPE and rHDPE are revolutionising industries by reducing dependence on virgin resources, lowering environmental impact, and fostering a circular economy. These polymers help divert millions of tonnes of waste from landfills and waterways, promoting efficient resource utilisation and minimising energy consumption. Their adoption across packaging, textiles, automotive, and infrastructure ensures strength, longevity, and compliance with sustainability standards. Through cutting-edge recycling processes, these materials enhance supply chain resilience, improve waste management practices, and drive eco-conscious innovation worldwide.

Our Commitment to a Sustainable Future

At Chemco, we recognise the urgent need for sustainable solutions to address the global plastic waste challenge. To create a lasting impact, we have strategically expanded our operations through backward integration, entering the post-consumer recycled (PCR) segment to ensure plastic waste is collected, processed, and transformed into high-quality recycled materials. By converting discarded PET bottles and other plastic waste into recycled polymers, we significantly reduce reliance on virgin plastics, minimising environmental impact while promoting a circular economy.

Through innovation and responsible manufacturing, Chemco produces high-performance rPET, rPP, rHDPE, rLLDPE and rLDPE granules that serve as sustainable alternatives across multiple industries. With this expansion, we now help brands achieve their Extended Producer Responsibility (EPR) targets, ensuring compliance with sustainability regulations while fostering a resource-efficient supply chain. By integrating cutting-edge recycling technologies, we are committed to reusing, repurposing, and reimagining plastics for long-term sustainability.

Eco-Conscious

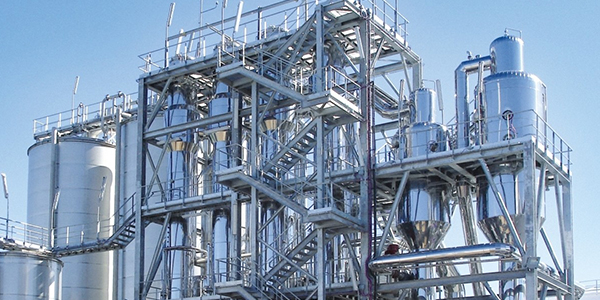

Sustainability is embedded in our manufacturing processes, where we optimise energy efficiency, water conservation, and waste reduction. Our state-of-the-art production facilities incorporate advanced decontamination and filtration systems, ensuring that every rPET flake meets global safety and compliance standards, including food-grade applications. With a focus on low carbon footprint operations, we continually refine our processes to reduce greenhouse gas emissions, making our products not only sustainable but also environmentally responsible.

Sustainable Benefits with rPET Manufacturing

CO2 Emissions

Energy Savings

Ecological Footprint

Employment

50000000

Number of PET bottles recycled

1500000

Kilogram’s of CO2 emissions saved

Zero Liquid Discharge

Our state-of-the-art bottle to bottle recycling unit is a Zero Liquid Discharge (ZLD) facility, ensuring 90%+ water recovery and zero wastewater discharge through advanced effluent treatment and RO systems. By integrating closed-loop water management, we minimise resource consumption while maintaining high-efficiency processing. Our facility is designed to maximise water reuse, significantly reducing freshwater dependency and supporting sustainable manufacturing practices. Through innovative filtration and purification technologies, we save millions of litres of water annually, reinforcing our commitment to environmental stewardship and circular economy principles.

Extended Producer Responsibility

With a strong rPET production capacity, we provide a consistent supply of high-quality rPP, rHDPE, rLLDPE and rLDPE granules, empowering brands to seamlessly meet their obligations while driving long-term sustainability. Our state-of-the-art manufacturing facilities and advanced recycling technologies ensure superior product quality and reliability, enabling our partners to maintain supply chain stability even in dynamic market conditions. By offering fully recyclable, high-performance resins across multiple polymer categories, we support businesses in achieving their sustainability targets and enhancing their environmental credentials. Through collaborative partnerships and continuous innovation, we are committed to helping industries transition to a circular economy, promoting responsible consumption and waste reduction across global markets.